SALVAGE:

In-Water INSPECTION:

- REASONS for Inspection

- Survey Inspection EQUIPMENT

- VESSEL In-Water Surveys

- Marine INFRASTRUCTURE Surveys

- MOORING Survey Inspection

- General Survey Inspections

- CORROSION Inspection

- Measuring Metal Thickness

- R.O.V. Inspection

In-Water CLEANING:

- WHY Cleaning? HOW to clean?

- HULL and RUDDER

- PROPELLER (cleaning/polishing)

- Marine INFRASTRUCTURE

- Sacrificial ANODES

- Water JETTING (high and low pressure)

In-Water REPAIRS, MAINTENANCE:

- Shipwork

- Cofferdam

- Marine INFRASTRUCTURE (overview)

- Single Point Mooring System (CALM & SALM)

- Wet WELDING & CUTTING

CIVIL WORKS & ENGINEERING:

- Dredging & Excavation off small BARGE

- Dredging, Jetting, Air-Lift, Dewatering by DIVERS

- Underwater DRILLING & BREAKING

- POST, PIPE, HOLLOW Section PILING with Portable hydraulic Hammer

- Maritime CONSTRUCTION

- Maritime DEMOLITION

- Marine OUTFALLS & Diffusers

- PIPELINES installation & maintenance

- Engineering

SEABED & EARTH ANCHORING:

- Cyclone Anchor Lines for rental

- MOORING Line: what's the (best) choice?

- HELICAL / SCREW Anchors information

- SCREW Anchors Mooring Systems

- PIPELING Anchoring

- Jetty & Walkway FOUNDATIONS screwing

- Expending Rock Anchors

- Grouted Rock Anchors

- Instant Foundation Anchors

- Earth Retention

![]()

![]()

Williams Form Engineering Corporation

- TOWAGE, Dive Support Vessel, Barges:

~ ~ ~ ~ ~ ~ ~ ~

Subsidiaries:

~ ~ ~ ~ ~ ~ ~ ~

Other useful Websites:

Diving

- ADAS Training Courses/job/careers

- New Zealand School of Commercial Diving Training

- Commercial Diving New Caledonia

Nautical Institutions

- IMCA International Marine Contractors Association

- BIMCO Baltic & International Maritime Council

- IMO International Maritime Organization

- Institute of Chartered Shipbrokers

- Institute of Marine Engineering Science and Technology

- International Federation of Shipmasters’ Associations

- International Ship Managers’ Association

- Maritime and Coastguard Agency

- Nautical Institute

- Lloyd’s List

Maritime Information

ABC Diving® Ltd

Port Vila, P.O. Box 3242 VANUATU South PacificComplete Diving Services to Vessels & Civil Engineering Industry

Please, contact us for:

VESSELS In-Water SURVEY (IWS - UWILD)

Implementation of equipment and skills in accordance with classification society requirements

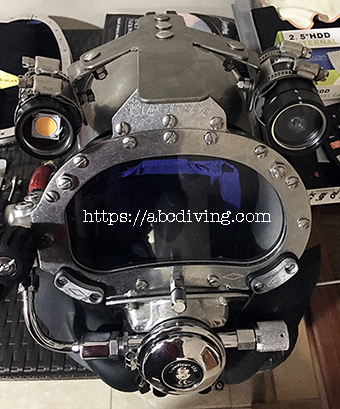

Commercial diving helmet set up with Full HD CCTV Camera (1933 H x 1088 V pixels) + Laser Pointer + light

- Complete HULL and/or RUNNING GEAR survey (struts, fairwaters, rope guards, props, rudders, bearings, etc.)

- Non-destructive TESTING (NDT*) of nominated areas on the hull shell plating and other appendages (Ultra thickness measurement)

- CORROSION damage inspection

- CATHODIC protection potential surveys: anode inspection measurement

- MARINE GROWTH inspection (and removal)

- DEBRIS inspection (and removal)

- SCOUR and STABILITY inspections.

* NDT Also called Non-Destructive Examination (NDE) or Non-Destructive Inspection (NDI).

Biofouling (CRMS compliant) or damage assessment survey

RUDDER, stock and bearings Class Survey

- Check STOCK for cracks and connection to rudder for loose or missing bolts or nuts.

- Check UPPER SUPPORT HOUSING for obvious wear, loose or missing bolts/nuts, locking devices and any missing components or presence of debris.

- Check TOP PORTION of RUDDER for missing filling plugs, corrosion and damage.

- Check INSPECTION PLATES for security of all bolts or nuts, and that no gasket material is hanging loose or parts of gaskets missing.

- Check LOWER PORTION of RUDDER drain plugs, lower inspection plate(s), and lower bearing.

- Check the clear MOVEMENT of Rudder from side to side (with diver on propeller shaft) and position checked for alignement;

- Measure rudder tracking edge to prop boss when rudder hard to port hand hard to starboard.

Sacrificial ANODES Suvey

- Check and report percentage WASTE + degree and coverage of PITTING

- Check if securely attached (LUGS or BOLTS corrosion/damage)

- On site Digital Still PHOTOGRAPHY Report

- REPLACEMENT process.

PROPELLER and Shafting Class Survey

- Check both for DAMAGE, LOCKING devices, and that no significant GAP exists in any JOINTS.

- Check each BLADE for CHIPPING, CRACKS, DISTORSION, 'polishing'.

- If variable PITCH, check each blade's securing flange, nuts and locking devices.

- Check that no DEBRIS, i.e. wire, rope, nylon, etc., has intruded on fittings and Clear

- Check each blade as it is 'feathered'.

- Check ROPE GUARD for security, fixtures and securing bolts and locking devices. Check that no line or wire rope has entered the gap between guard and propeller and Clear

- If 'A' brackets are fitted, check for damage and any cracks, particularly the welds or attachment devices to both hull and shaft housing.

- Check all bearings and shafts for OIL LEAKS.

TRANSDUCER Inspection for replacement

- Check dimensions

- Check nature of the body material

- Check any defect.

You may be interested to know about: our video and still-photography equipment

°°°°°°°°°°°°°°